Technologies

Elemental Technologies

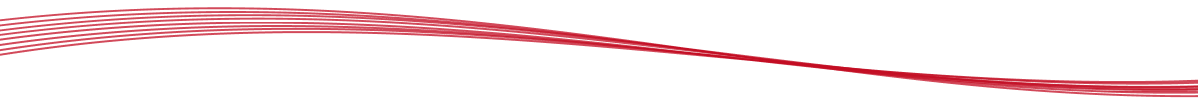

Unique industry-leading nanotechnology controls object size, shape, surface condition, and structure at the nano level.

We help you realize new functions and multifunctionality for our customers' businesses.

In manufacturing, controlling the size, shape, surface condition, and structure of objects at the nano level is the key to developing new functions, higher functionality, and multifunctionality.

Our industry-leading core nanotechnologies are helping customers create new value and aiding the chemical industry's efforts for carbon neutrality and a circular economy.

Challenges of Client's Business

Four Core Nanotechnologies

JGC Catalysts and Chemicals has established four core technologies focusing on fundamental properties of nanoparticles: shape, size, surface, and bulk.

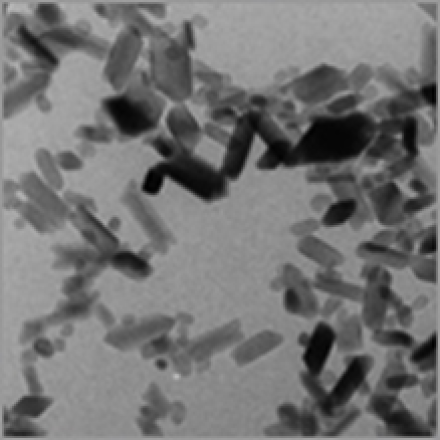

(1) Nanoparticle preparation technology

Technology that prepares nano-level, super-fine particles (colloidal particles).

Nanoparticles can be made into targeted sizes and their shapes freely manipulated to form chains, rods, spheres with bumpy surfaces, and much more.

Chain-like

Rod-like

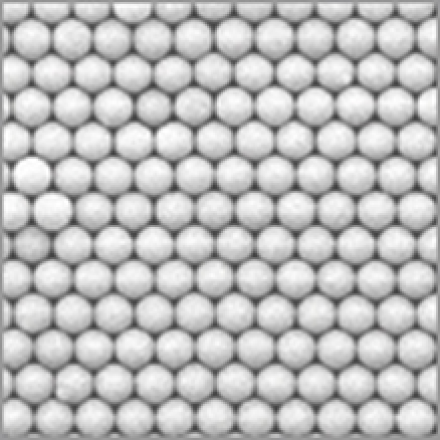

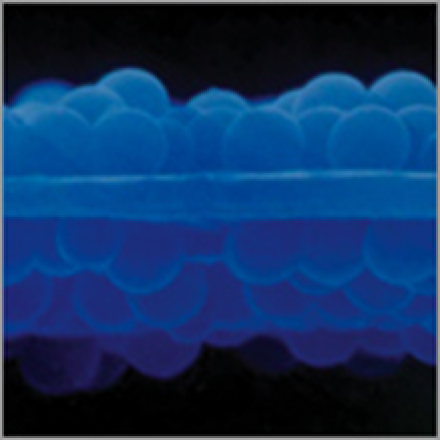

(2) Nanoparticle alignment control technology

Technology that creates single or multiple layers of fine and super-fine particles and arranges them in compound arrays.

Functions this can achieve include light scattering with a single-phase array or anti-reflection effect by a multilayer array.

Microspherical Silica Alignment

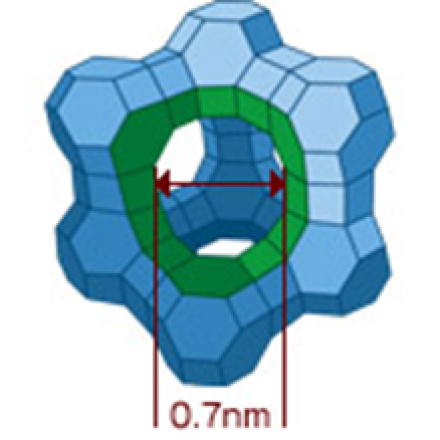

(3) Nano pore structure control technology

Technology that controls nano pore distribution within narrow margins.

Pore size can be varied from micro to macro to suit the application.

Nano Pore in Zeolite

Fibrous Mesh

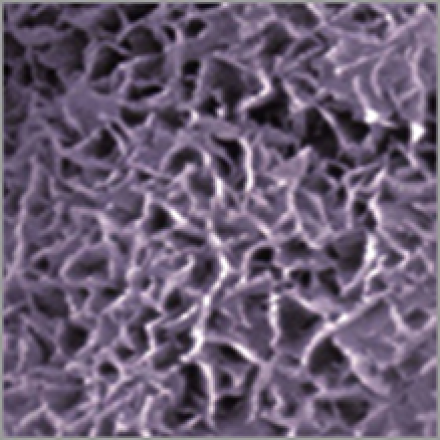

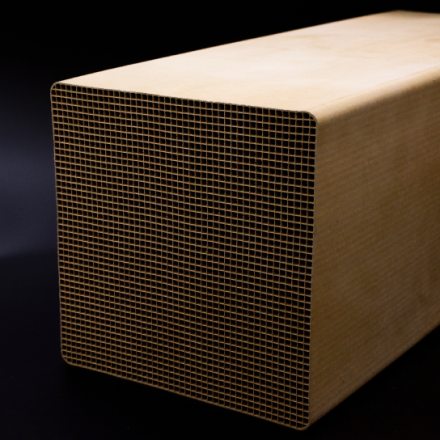

(4) Macro structure control technology

Technology that controls macro structures enables molding to spherical, tablet, honeycomb, and other forms suited to a variety of processes.

Honeycomb Type

Macaroni Type

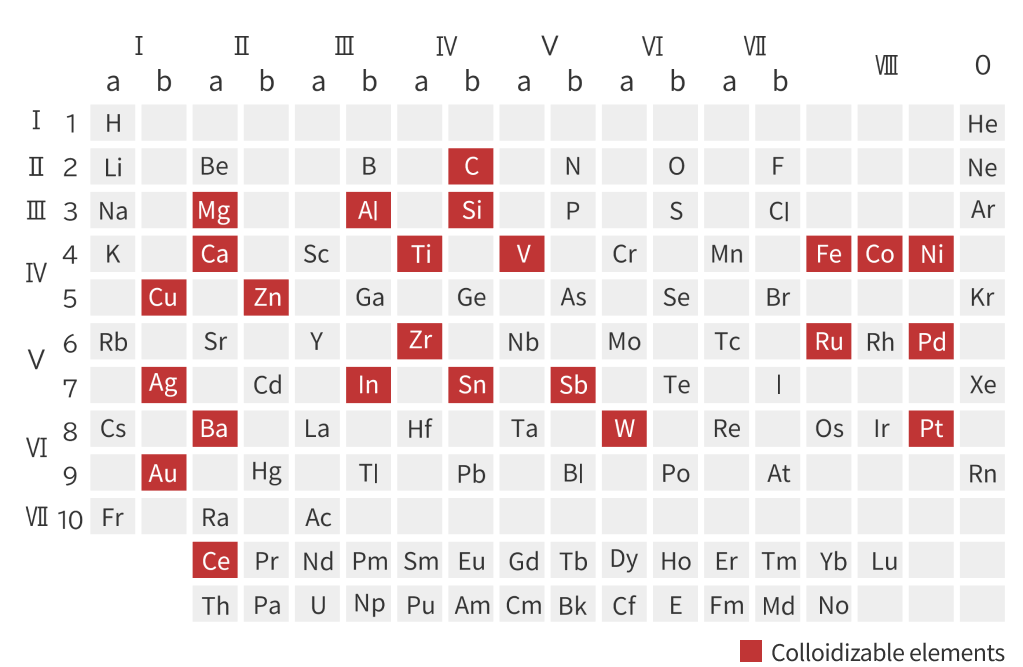

Basic Colloidal Technology

Technology that can process 24 elements into colloids.

Inquire for details.

Development & Manufacturing

Customers often give us an idea of what kind of catalyst they're looking for and ask if we can deliver. This prompts us to prepare a sample for the customer to evaluate Through this "Sample Dialogue", we help you bring your concepts to reality. This dialogue is possible because our development system brings research, production, and technical sales staff together.