Research & Development・Manufacturing

Research & Development

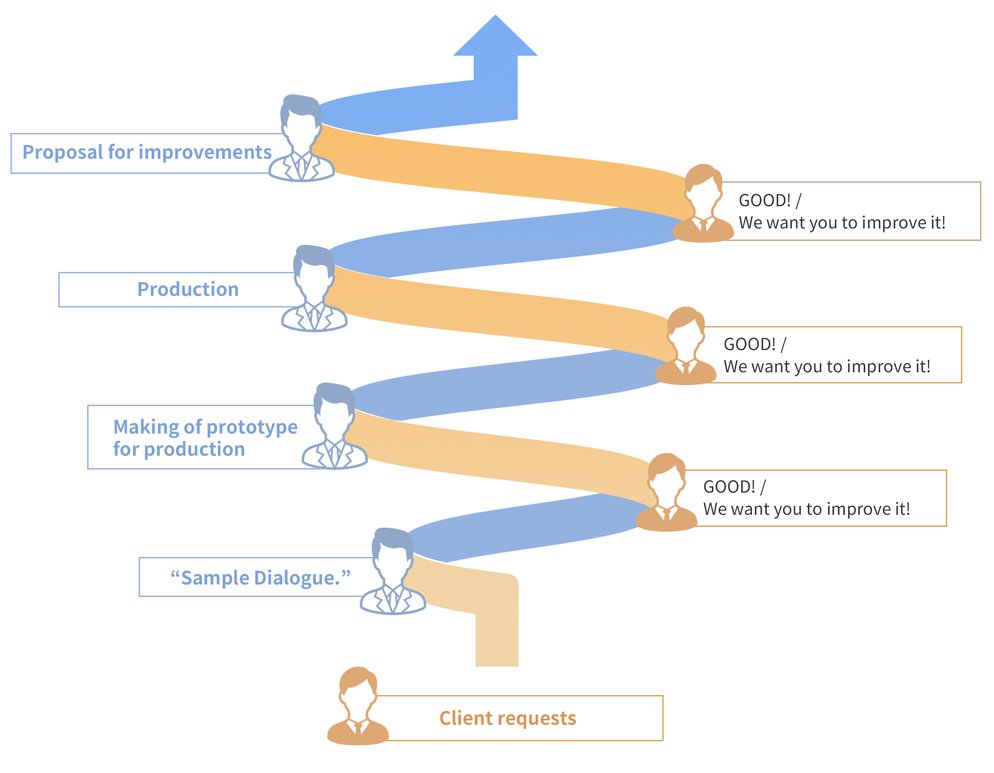

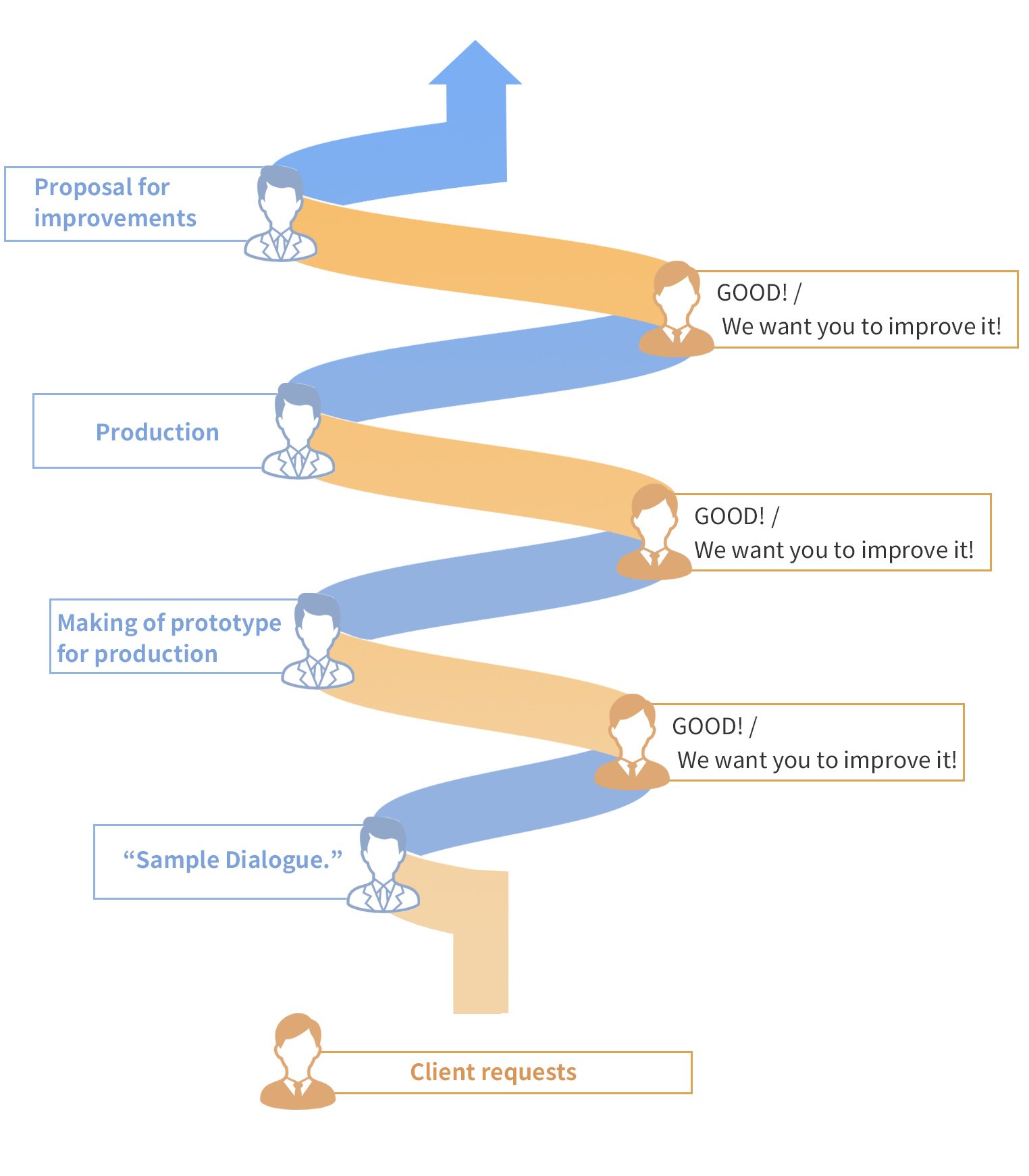

When customers describe a catalyst and ask if we can create it, we respond with a sample.

We help you bring your concepts to reality.

Sometimes customers ask, "Can you make something like this?"

When we get customer inquiries that are still vague, instead of replying with words, we make a trial sample that essentially says, "Is this what you want?"

Our research, production, and technical sales staff work together to realize our customers' implicit needs through a process of "Sample Dialogue."

Benefit

point 01

Diverse matrix technology built on a track record of many years

point 02

Design that starts with major feedstocks: a global rarity

point 03

Technical services that work with your business

Development always begins with a vague idea.

Work with us to bring your ideas to reality.

JGC Catalysts and Chemicals listens to our customers' vague ideas and engages in sample dialogue using our technology with its years-long track record.

Through a process that moves from prototyping to mass production to suggestions for making improvements through our technical services, we gradually develop our customers' ideas.

Spiral of co-creation

Do you have decarbonization issues to research?

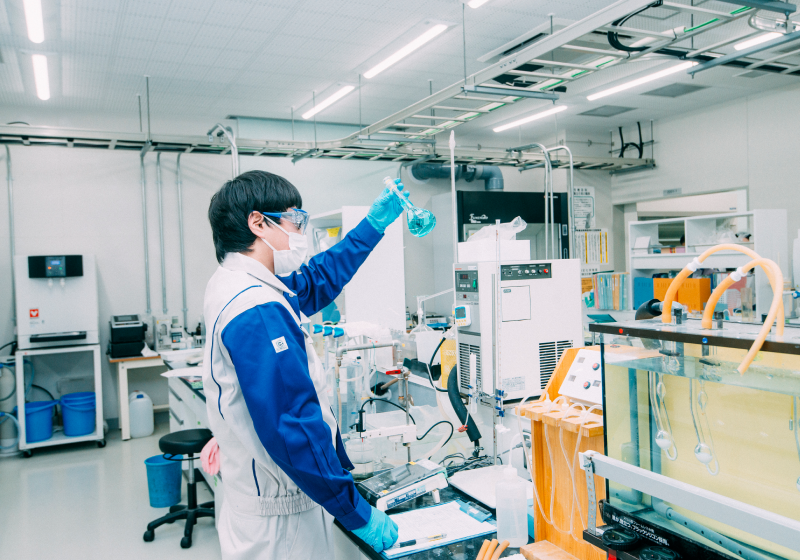

Our catalyst and adsorbent R&D is helping to meet decarbonization needs.

JGC Catalysts and Chemicals researches and develops products and technologies to meet the challenge of decarbonization.

To increase the pace of decarbonization technology R&D, we are innovating our R&D and analysis equipment and creating high-function products.

Contact us if you have decarbonization issues to research.

| Products | Fields/Applications | Functions/Features |

|---|---|---|

| Catalysts | Hydrogen Carrier | Catalysts that crack ammonia into hydrogen |

|

SAF e-fuel e-methane |

Catalysts that are essential for the process of upcycling sustainable feedstocks such as hydrogen, ammonia, carbon dioxide, waste plastics, waste tires, waste cooking oil, and biomass | |

| Adsorbents | Adsorbents that remove substances like chlorine and sulfur compounds that are problematic in using waste plastics and other materials as feedstock Especially for chlorine compounds, we have developed products that meet a variety of needs since they can be used for both organic and inorganic systems with their differing adsorption mechanisms. |

|

| Factory / Thermal power plant | Adsorbents that separate and recover CO2 Use of materials like zeolite that offer high robustness against adsorption inhibitors |

Manufacturing

Flexible customer support thanks to an integrated manufacturing system.

We achieve the ideal business model for our customers.

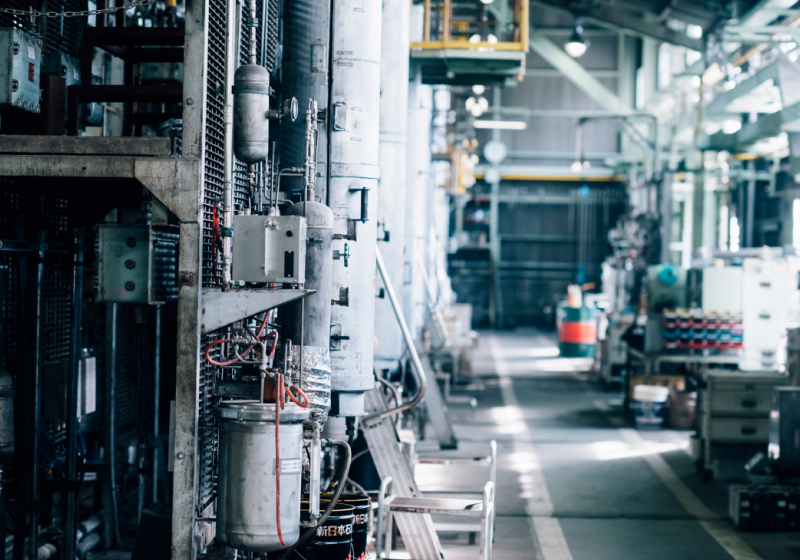

Backed by process know-how at every step, our manufacturing system integrates the reaction, drying, impregnation, blending and kneading, molding, and activation processes. This level of integration helps us meet our customers' diverse needs. (We can also provide contract and fabless support for unit processes.)

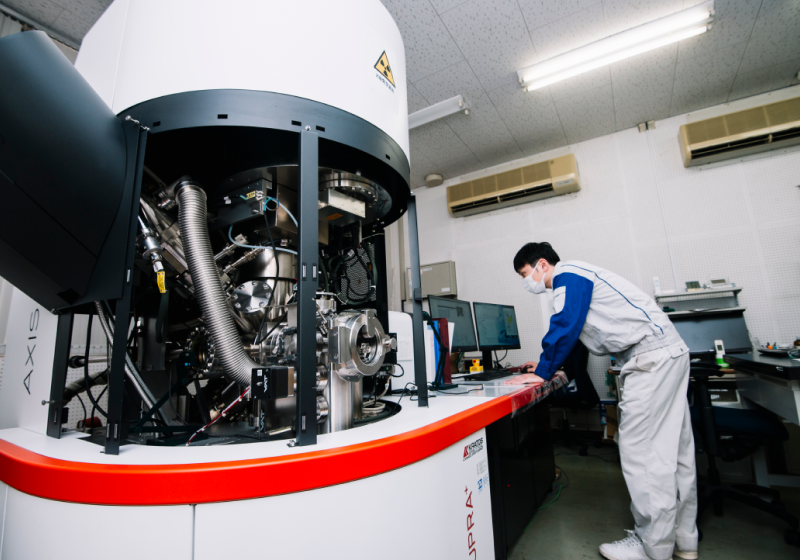

Moreover, our product evaluation system utilizes advanced analytical instruments to improve efficiency to shorten production time, minimize operating costs and stabilize quality.

With advanced manufacturing technologies and equipment and comprehensive quality control, we help our customers realize their ideal business model.

Main Catalyst Production Facilities

| Process | Equipment | |

|---|---|---|

| Reaction | Precipitation |

・Glass lining tank ・SUS tank ・Autoclave |

| Washing / Filtration |

・Filter press ・Oliver filter |

|

| Drying |

・Compartment tray dryer ・Band dryer ・Spray dryer ・Slurry dryer |

|

| Impregnation | ・Conical dryer | |

| Mixing and Kneading |

・Kneader ・Intensive mixer |

|

| Molding |

・Extruder ・Tablet press |

|

| Activation | Firing |

・Cage-type firing furnace (Batch firing, - 1,300℃) ・Rotary kiln ・Tunnel firing furnace (Continuous high-temperature firing, - 1,400℃) |

| Reduction stabilization | ・Reduction tower | |

Main Analytical Instruments

| Tests and Analyses Category | Equipment |

|---|---|

| Physical Properties |

・Attrition Resistance Tester ・XXRD(A-Ray Diffraction) ・XRD(A-Ray Diffraction) ・TPD(Temperature-programmed Desorption) |

| Chemical Analysis |

・XFS(X-Ray Fluorescence Spectrometer) ・ICP(Inductively Coupled Plasma-Optical Emission Spectroscopy) |

| Special Analysis |

・XPS(X-Ray Photoelectron Spectroscopy) ・SEM(Scanning Electron Microscopy) ・FE-TEM(Field Emission Transmission Electron Microscopy) |

| Activity Tests |

・FCC MAT(FCC Micro Activity Test) ・Performance Test for Hydroprocessing Catalysts ・Performance Test for DeNOX Catalysts |