Chemical

About Us

Welcome!

Our technical sales staff listen closely to determine what problems our customers are having with their current catalysts.

Many of the technical sales staff at JGC Catalysts and Chemicals' Chemical Unit are professionals with careers in R&D and deep knowledge of catalysts.

They engage customers in close dialogue, considering the technological perspective to learn what kind of catalysts they need, which might include catalysts that promote carbon neutrality or enhance the function of the customer's products. Staff will then work together with research and manufacturing to quickly realize the customer's catalyst goals.

Benefit

point01

High-quality customization

Detailed customization is not easy to achieve.

JGC Catalysts and Chemicals approaches the task with a rich product lineup and a variety of production facilities and systems, with which we can offer various customizations and precise support for our customers' business.

point02

Development capabilities for everything from lab scale to commercialization

With our production facilities, JGC Catalysts and Chemicals can achieve lab scale, pilot scale, actual production, and even commercialization.

We don't just develop our own products. We also offer joint development, industrialization support based on customer-developed catalyst preparation formulations, and contract manufacturing.

We also provide products suited to our customers' production processes with basic technologies that no other company can offer. This ranges from particle design using nano control technology to catalyst molding using macro-control technology.

point03

Technical service based on experimentation and past results data

JGC Catalysts and Chemicals has proprietary evaluation technology that predicts catalyst life.

It simulates the reaction state of customer processes so we can recommend the best catalyst and forecast how often a catalyst needs to be replaced.

With our extensive track record, we can provide accurate forecasts based on actual data for our customers' businesses.

Product

- Hydrogenation and Dehydrogenation

- Adsorption

- Nickel-based

- Hydrogenation and Dehydrogenation

- Adsorption

- Nickel-based

- Production of Ambient Gases

- Nickel-based

- Hydrogenation and Dehydrogenation

- Nickel-based

- Hydrogenation and Dehydrogenation

- Nickel-based

- Production of Ambient Gases

- Nickel-based

- Hydrogenation and Dehydrogenation

- Adsorption

- Copper-based

- Hydrogenation and Dehydrogenation

- Adsorption

- Copper-based

- Adsorption

- Copper-based

- Gas Purification

- Copper-based

- Hydrogenation and Dehydrogenation

- Copper-based

- Hydrogenation and Dehydrogenation

- Copper-based

- Carriers

- Silica/alumina-based

- Isomerization, alkylation, dehydration, hydration

- Carriers

- Silica/alumina-based

- Isomerization, alkylation, dehydration, hydration

- Carriers

- Silica/alumina-based

- Isomerization, alkylation, dehydration, hydration

- Carriers

- Silica/alumina-based

- Adsorption

- Silica/alumina-based

- Others

- Adsorption

- Silica/alumina-based

- Others

- Adsorption

- Zinc-based

- Hydrogenation and Dehydrogenation

- Precious metal-based

- Hydrogenation and Dehydrogenation

- Precious metal-based

- Hydrogenation and Dehydrogenation

- Precious metal-based

- Hydrogenation and Dehydrogenation

- Precious metal-based

- Isomerization, alkylation, dehydration, hydration

- Carriers

- Zeolite-based

Development & Manufacturing

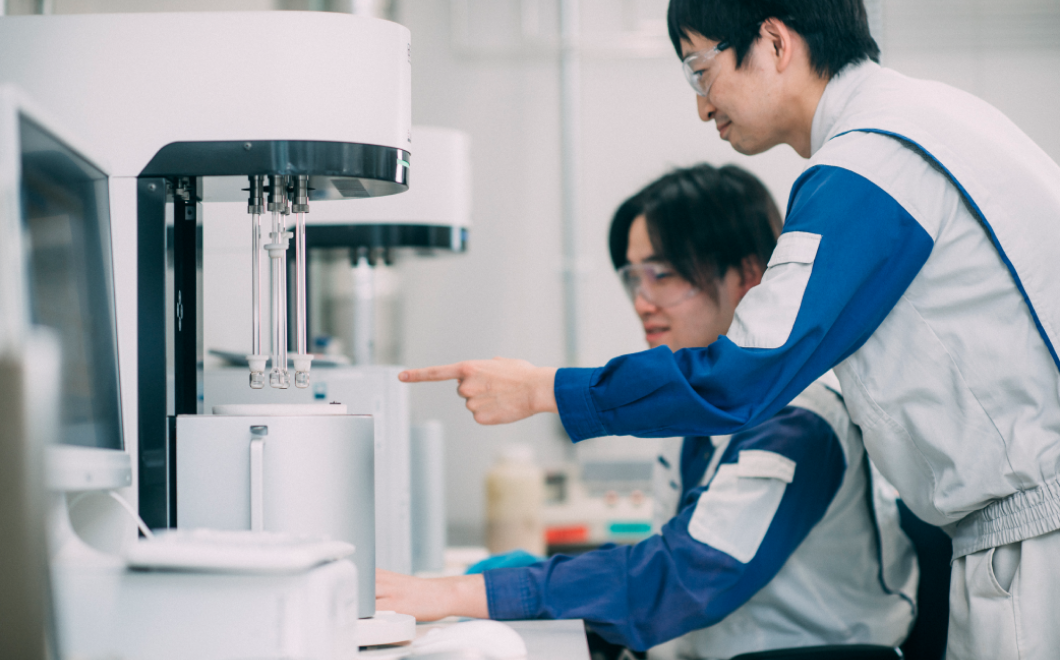

Customers often give us an idea of what kind of catalyst they're looking for and ask if we can deliver. This prompts us to prepare a sample for the customer to evaluate.

Through this "Sample Dialogue", we help you bring your concepts to reality.。

This dialogue is possible because our development system brings research, production, and technical sales staff together.