To bring about the realization of catalyst development with value, and which prioritizes the requirements of our customers, we provide optimal solutions based on the concept of optimizing the development plan, minimizing development cost, and minimizing development time.

Through a co-creative spiral model, we pursue the development of new technologies and high-quality production, bringing about advanced processes in the operation of many diverse production facilities.

Through collaboration with customers, we provide support for opening up the global market by creating new values and developing catalysts with enhanced competitiveness.

We offer modification and customization of catalysts developed by the company (“proper catalysts”) to suit the specific needs of our customers, and support the industrialization of these products for dedicated use based on customers’ prescriptions.

Commissioned production focuses on providing “fabless” support (provision of an integrated production system) that helps customers build their ideal business models.

Catalyst Development

Through the fusion of our customers’ outstanding technologies and the catalyst development technologies that we have built up over our long history, we provide support for the creation of new values and the creation of competitive products for the global market.

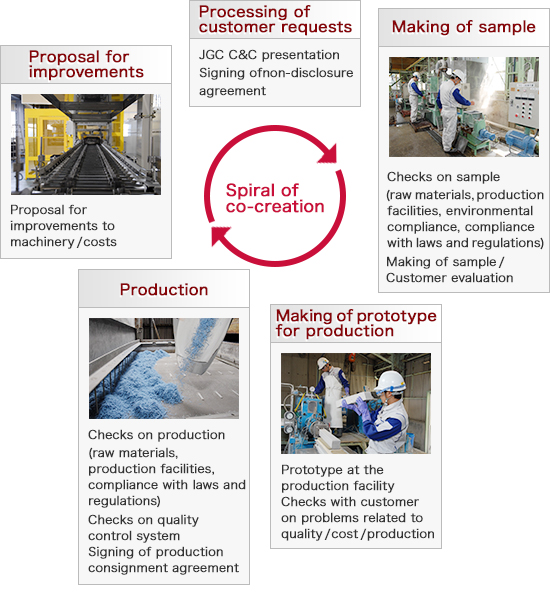

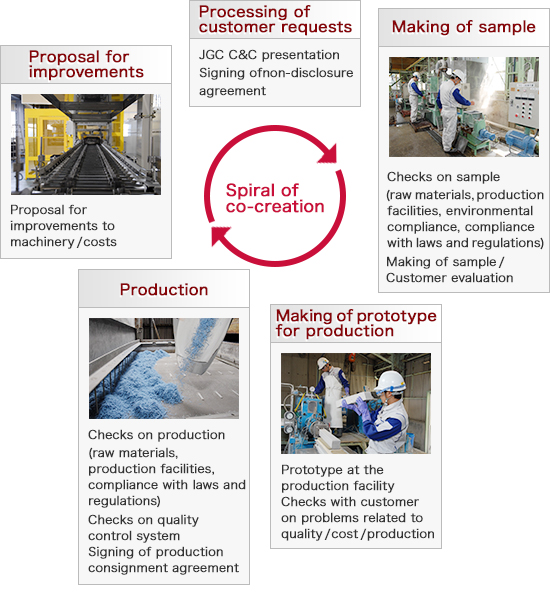

Based on the co-creative spiral model, we repeatedly carry out the processes of prototyping, development, manufacturing, and improvement as we strive to achieve optimization, and bring about the efficient operation of various processes.

We ensure security for important development information through the “building, operation, and management” cycle under a robust security system.

<Basic flow for the creation of new values>

Commissioned Production

We provide integrated manufacturing services from reaction, drying, impregnation, mixing and kneading, molding, and activation processes, founded upon the experience and track record, as well as the diverse equipment and process knowhow for various processes that we have built up over many years. (We accept commissions for unit processes.)

We strive to streamline processes to reduce production time, minimize operational costs, and stabilize quality, and have established an advanced production system in order to provide customers with services that are closer to them.

Through cutting-edge production technology and equipment, and a thorough quality control system, we have established a flexible production environment that suits our customers’ needs. We provide support for the realization of comfortable business models that are ideal for our customers.

【Main catalyst production facilities】

| Process |

Equipment |

Examples of JGC C&C’s technology |

| Reaction |

Precipitation |

Glass lining tank

SUS tank

Autoclave |

|

| Washing/filtration |

Filter press

Oliver filter |

|

| Drying |

compartment tray dryer

Band dryer

Spray dryer

Slurry dryer |

|

| Impregnation |

Conical dryer |

|

| Mixing and kneading |

Kneader

Intensive mixer |

|

| Molding |

Extruder

Tablet press |

○ |

| Activation |

Firing |

Cage-type firing furnace (Batch firing, - 1,300℃)

Rotary kiln

Tunnel firing furnace (Continuous high-temperature firing, - 1,400℃) |

|

| Reduction stabilization |

Reduction tower |

○ |

【Main analytical instruments】

| Physical properties |

Attrition Resistance Tester

XXRD(A-Ray Diffraction)

XRD(A-Ray Diffraction)

TPD(Temperature-programmed Desorption) |

| Chemical Analysis |

XFS(X-Ray Fluorescence Spectrometer)

ICP(Inductively Coupled Plasma-Optical Emission Spectroscopy) |

| Special Analysis |

XPS(X-Ray Photoelectron Spectroscopy)

SEM(Scanning Electron Microscopy)

FE-TEM(Field Emission Transmission Electron Microscopy) |

| Activity Tests |

FCC MAT(FCC Micro Activity Test)

Performance Test for Hydroprocessing Catalysts

Performance Test for DeNOX Catalysts |

【Examples of JGC C&C’s technology】

(1) Molding technology

In addition to extrusion and tablet pressing technology for fixed-bed reactors, we also possess granulation molding technology that is used in fluid-bed reactors, which is representative for FCC catalysts.

(Representative forms: Tablet, ring, four-leaved, macaroni, honeycomb, bead, etc.)

Tablet 5mmΦ

Ring 5mmΦ

Four-leaved 1/18"(1.4mm)

Macaroni 1/4"(6.4mm)

Honeycomb 150mmロ

Bead 0.7mmΦ

(2) Reduction stabilization technology

In the petrochemicals field, JGC C&C possesses reduction stabilization technology built up for many years through the production of fixed-bed nickel catalysts.